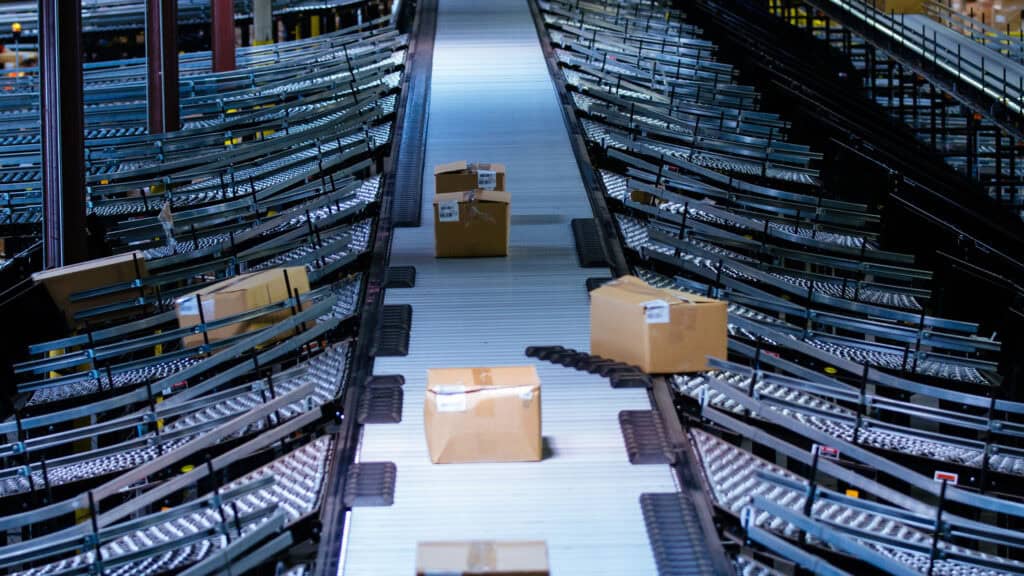

Shipping & Sortation systems

Divert and sort rapidly

Product sortation is one of the biggest challenges’ companies face in the process of getting their product to market. Sortation systems separate products for induction into individual lanes typically associated with an outbound destination. Various types of sortation and conveyor systems are often connected to comprise a fully functioning material handling solution.

Sortation System Types

Accuracy and timeliness of order fulfillment have never been a higher concern until now. Combine these factors with the increasing requirement to reduce resources and trim costs within the distribution channel, makes it easy to understand the benefits and efficiencies automated sortation systems deliver. With the rise of e-commerce, sortation and conveyor systems have evolved from simply transporting cases for store replenishment to handling a variety of individual items and packaging types, including cases, totes and polybags. This evolution has introduced new order fulfillment complexities.

- Increase throughput to keep pace with high order volumes and SKU proliferation

- Improve order accuracy to minimize returns processing

- Develop cross-docking processes to alleviate storage and handling requirements

- Integrate with warehouse execution systems to drive greater levels of automation

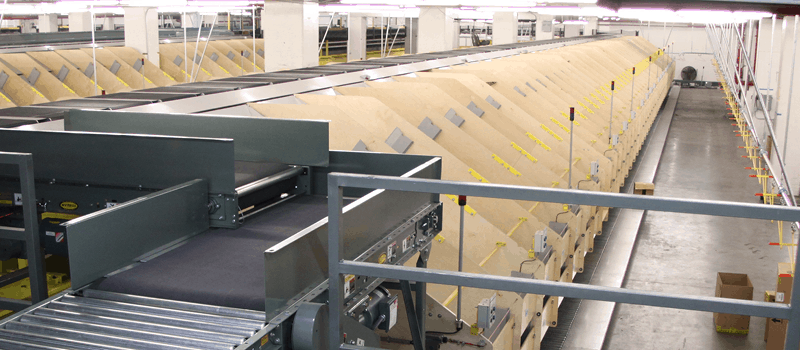

Sliding Shoe Sorter

High speed sorter utilizing aluminum slats that have plastic shoes that slide across them to divert cartons either left or right (bi-directional) to required sort destinations.

Benefits

- Capable of sortation rates up to 650 feet per minute (FPM)

- Angle of diverts can be modified

- High-speed sortation of both medium and larger cartons

- Plastic shoes are designed to gently push cartons, and can be removed easily in the event of mechanical service or jams

Narrow Belt Sorter

A series of narrow belts, each with its own take-up, span the length of the conveyor. High-friction divert wheels rise between the belts, diverting product to it’s destination.

Benefits

- Capable of sortation rates up to 350 feet per minute (FPM)

- Narrow belt design enables a smaller sorter space footprint

- Ideal for high-speed sortation of small to medium-sized cartons

- Diverts can be placed at a diagonal or right angle to maximize the amount of sort lines

Push Tray Sorter

High speed sorter with tray segments utilizing a positive divert to gently push items or polybags off the tray and slide them into a sortation chute.

Benefits

- Capable of rates greater than 225 trays per minute

- Modular design of each tray unit means each sorter can be scaled exactly to warehouse size

- Ideal solution for handling varying carton dimensions and types

- Lower cost when compared with other non-tray sorters

Split Tray Sorter

Sometimes also referred to as a bomb-bay sorter, split tray sorters allow manual induction at a terminal, then carry parcels to a chute section, swinging the tray down and dropping the parcel down the indicated chute.

Benefits

- Capable of rates greater than 280 trays per minute

- Maximizes outbound destinations within a condensed sorter footprint

- Ideal solution for handling polybags or parcels

- Lower cost when compared with other non-tray sorters. Trays can be single, double, or quad drop.

Tilt-Tray Sorter

Also known as a cross-belt sorter, a tilt-tray does exactly what the name implies. Belted or static tray platforms convey around a loop, passing an induction terminal. Once a carton, item, or parcel is placed on a tray, it will travel to the indicated chute and tilt it’s tray carriage, releasing the item down.

Benefits

- Capable of rates greater than 350 trays per minute

- Ideal for rapid sortation of smaller parcels or items for ecommerce fulfillment

- Trays can be modified to the item or carton type and size

- Loop configuration and multiple outfeeding diverts benefit operators sorting to a high number of destinations

Take the first step for true efficiency

Send Century a message to start planning your next distribution facility automation optimization project. Provide any project details in your submission, and an Automation Expert will respond promptly with next steps on your request.