Robotic Arm Material Handling Systems

Labor-saving robotic material handling

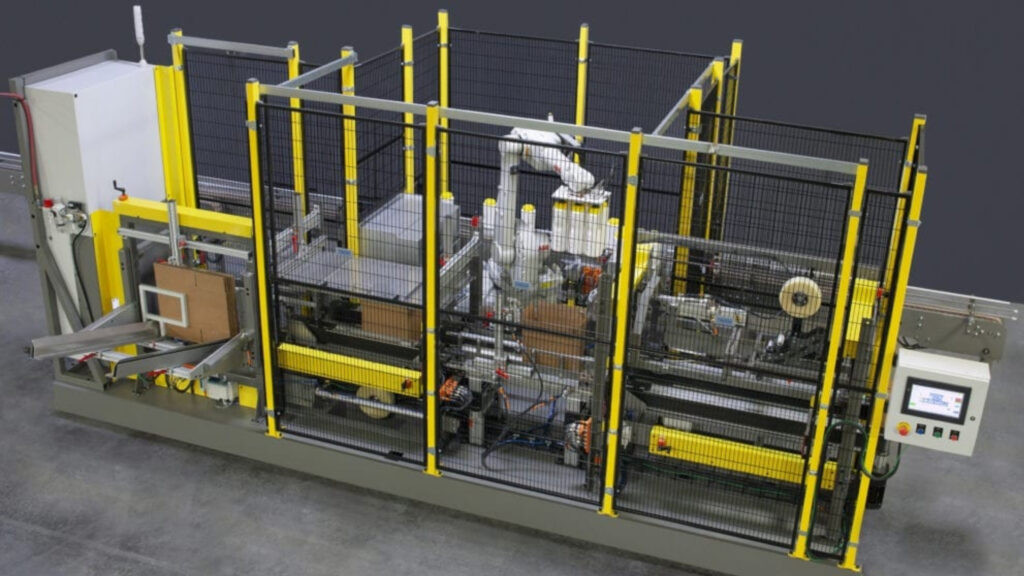

Robotic palletizing solutions allow users to automate manual palletizing and layer building where high case volumes provide attractive business case scenarios. A wide variety of robots and end of arm tooling can accommodate most carton sizes and complex layer build configurations for pallets. Robotic palletizing cells are fed with sequencing sortation systems. Completed pallets are conveying from a robotic cell to an inline stretch wrap operation.

Articulating Arm

Articulating arm solutions allow users to automate end-of-production line palletizing where high case volumes provide attractive business case scenarios. A wide variety of palletizing solutions and end of arm tooling can accommodate most carton sizes and complex layer build configurations for pallets. Robotic palletizing cells are fed with sequencing sortation systems. Completed pallets are conveying from a robotic cell to an inline stretch wrap operation.

Benefits

- Deployed in a minimal footprint palletizing cell

- Arm tooling can be customized according to the product being handled

- Can be integrated into a conveyor system

- Arm movements can be fine-tuned for increased functionality

Palletizing and Depalletizing

An automatic robotic palletizer solution places cartons in a pallet formation in a cell, picking up cartons from one or more inducting conveyor lines.

For depalletizing – the reverse is done. A pallet is brought to a staging area or inducted from a pallet handling conveyor. The arm will transport cartons to a single conveyor or multiple lines.

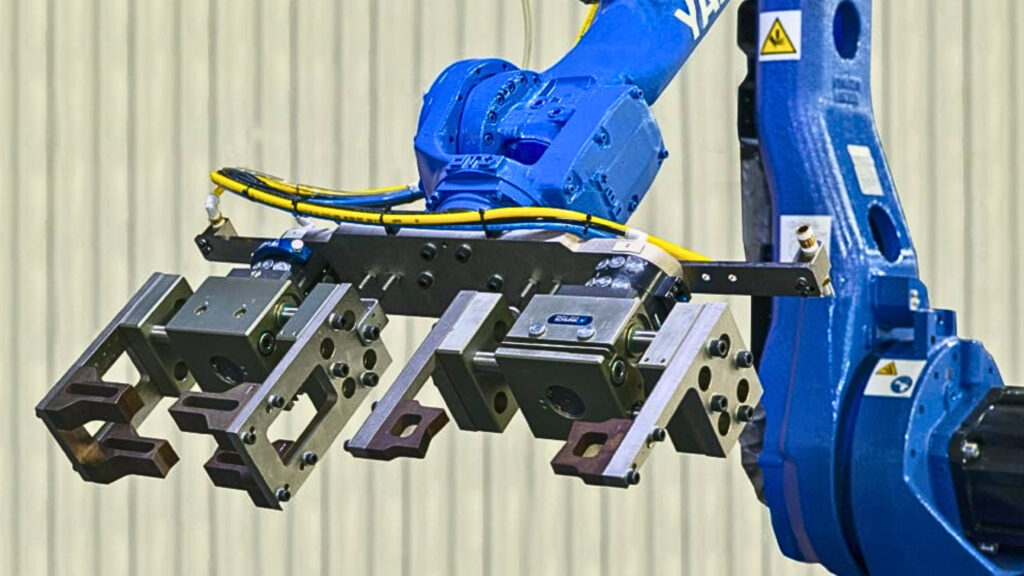

Specialized Arm Tooling

Attachments can be added to the end-of arm to provide specialized handling of a variety of products and containers. Tooling can range from handling of small items for picking, to large non-conveyables – customized exactly for product dimensions and weights.

Pressurized vacuum suction cups are a popular end-of-arm attachement, but customized solutions can handle bulky items, such as pails, totes, drums, slip sheets, and more.

Case Forming, Packing, Sealing

Robotic arms are precise enough to fully form a carton and pack it, outfeeding to a conveyor line that seals the box. Cells can be configured per the product handled and process required, and multiple cells can be deployed on a single line to maximize automation.

Specialized tooling can be modified to handle certain products, which is ideal for operators packing cartons with similarly sized SKUs.

Mixed Case Palletizing

To palletize mixed cases, a robotic arm travels on a straight rail line or an overhead gantry, flanked by pallets, and automatically picks cartons or containers onto a platform. Pallets are inducted from a conveyor, stored in a racking structure, or simply placed alongside the arm in a staging area.

Once a mixed pallet is complete, the palletizing platform inducts to an outfeeding source (such as a conveyor that leads to an automatic stretch wrapper).

Cobot

A robotic arm designed to work in tandem with associates. Cobots operate at slower speeds and have additional sensors and cameras to detect nearby workers. Because of this, workers can pick from or induct to a cobot, eliminating the need for a cell.

Cobots are ideal for picking operations, mainly to assist associates in order fulfillment.

Take the first step for true efficiency

Send Century a message to start planning your next distribution facility automation optimization project. Provide any project details in your submission, and an Automation Expert will respond promptly with next steps on your request.