When it comes to increasing the efficiency of your distribution center, few solutions match the benefits of an automation system. But, therein lies the question of WHICH automation system. Between all the advances in material handling tech and how specialized automation has become, it can be a massive undertaking in finding the right system for your DC.

One solution does maintain a consistent presence in today’s modern distribution center- conveyors. Throughout the years, conveyor systems have been a staple automation choice for quick and stable movement of goods. The reason for its proliferation? Simplicity.

At its core, a conveyor system is a continuously moving platform that transports an item from one location to another. Of course, various other systems can be integrated into a conveyor, and technological advancements have brought modern conveyors a long way from its first inception, but conveyors are a classic case of “if it works, don’t change it”.

This testament holds true today, even in the ever-changing industrial automation market. Conveyors are widely used for many applications and can be scaled exactly to what’s needed. Giants like Amazon, even with their fleet of proprietary robots, utilize conveyors in their many distribution centers. On the other end of the scale, small distribution centers can see positive benefits from just a single line.

For any distribution center looking to automate, a conveyor system has a few core functions that should place it in the running for serious consideration:

- Rapid, Continuous Movement

- Durability

- Integration Capable

- Accurate Distribution

- Tailored Engineering

Let’s go through each:

Rapid, Continuous Movement

The #1 benefit of a conveyor system over anything else is its ability to quickly transport a continuous line of product across a distribution center. Conveyor systems can complete an array of material handling processes, including but not limited to:

- Picking

- Case forming and sealing

- Print and apply

- Palletizing and depalletizing

- Sortation and distribution

- EOL loading

- WCS and WMS functions

….all within one singular system. This keeps items moving to their destination in the shortest time possible, with little manual interaction.

Conveyors are ideal for distribution centers that process a large amount of orders per day. In Century’s experience, a good starting throughput rate to justify the power of a conveyor system hovers around 1,000 cartons shipped a day. Some high-output operations, like those moving polybags, or crossdocking, can see daily output reach past 40,000 cartons shipped. If that’s the rate you’re looking to achieve at your distribution center, keep on reading.

Durability

Conveyors are famously durable, with the average lifespan typically hovering around 25 years. With routine maintenance, conveyors are extremely reliable, provided that the system is functioning as intended.

Aside from the initial startup, conveyors are extremely self-sufficient. A distribution center won’t have to hire a specific engineer to operate the system as some other solutions might require. Employees can be easily trained to work with the conveyor safely and efficiently. Maintenance can be completed by a conveyor service partner (like us!), or an internal repairman on-site with minimal downtime. In some situations, a manufacturer or servicer can remotely VPN into the controls platform of the conveyor and troubleshoot errors on the fly, without ever having to send a specialized technician.

The difference between a conveyor and any other solution is in its simplicity. AGVs, AMRs, ASRS’, and other robotic solutions heavily rely on the environment, and its programmed abilities. All its functions are contained within one singular system, whereas a conveyor combines multiple systems into a linear flow.

Conveyors are designed to be able to be easily repaired, while robotic systems are more advanced and may require a specialist. To use an analogy, imagine working on a naturally aspired vehicle made in 2002, vs. an electric car produced in 2022. The 2002 vehicle is much more accessible to repair and maintain, while the electric car has to be brought to the manufacturer to update systems and provide advanced high-voltage service. This isn’t to say that conveyors are “low-tech”, but not as complex in how it functions as some other systems.

Integration Capable

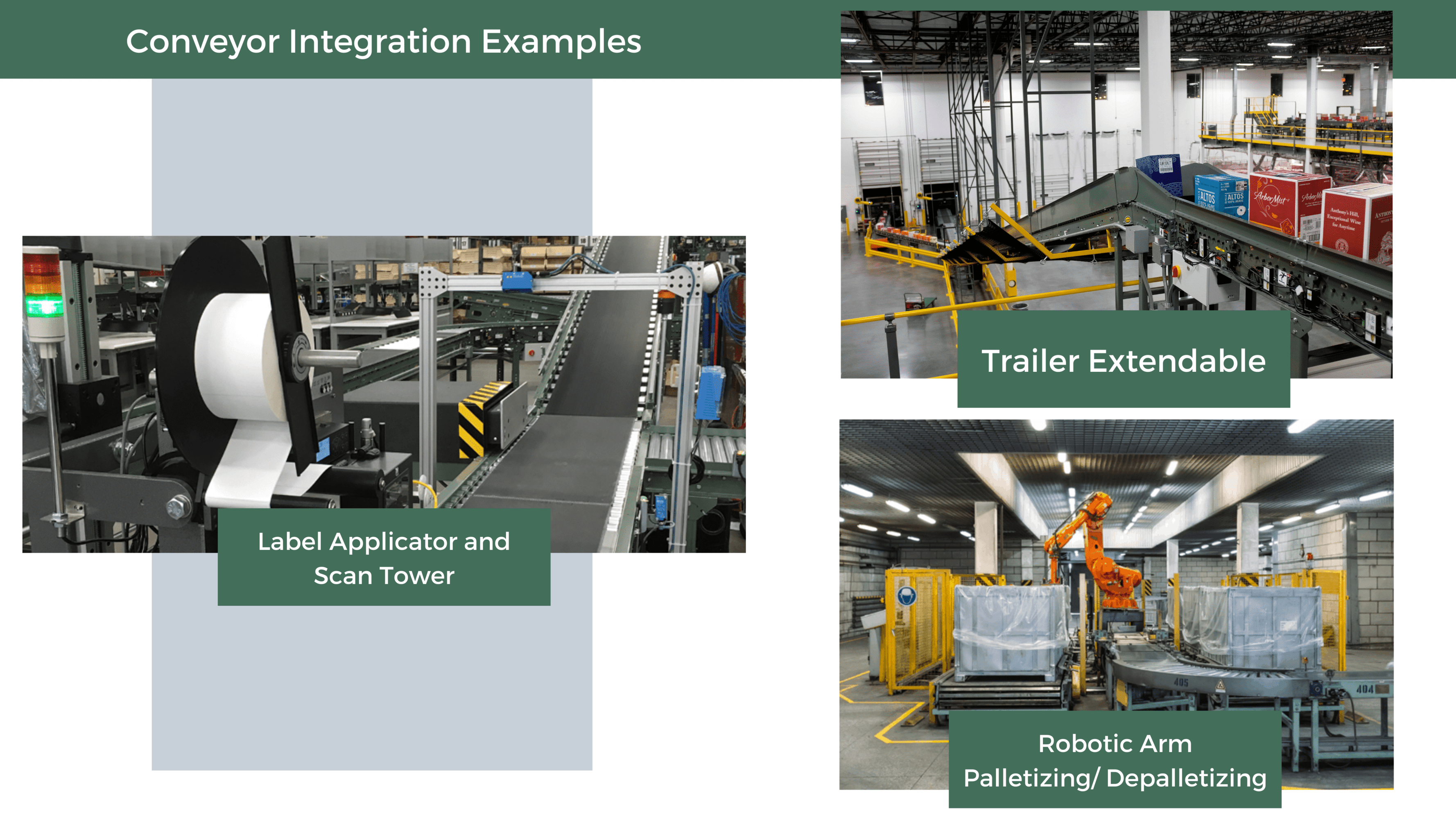

Conveyor systems are plenty customizable and have the ability to slot in with automation hardware and software with relative ease. It’s entirely feasible to install a conveyor system, and then implement additional systems afterward once it’s needed, or when the budget can be allocated.

Typically, a conveyor system can integrate most solutions, even robotics. If your distribution center has complex operations and a variety of different automation is used, for the most part, a conveyor system can infeed or outfeed to the machines that are operating.

For example, a large distribution center has a conveyor system but wants to integrate a carton sealer after packing operations. Instead of having to remove an old system and re-install a new one, a section of the conveyor is torn out, and the case sealer is installed in its place.

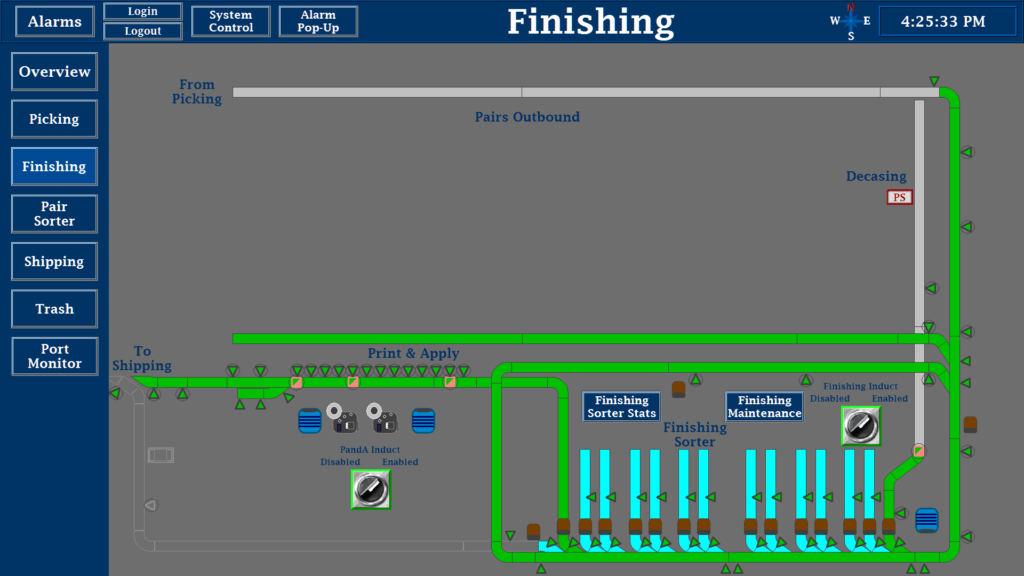

In terms of software, depending on the manufacturer, a Warehouse Control System application can be implemented into your WMS. This enables expanded functionality, reporting, data collection, tracking, and error analysis. Century uses a proprietary platform called ConveyorWorks, but there exist plenty of other HMI software options.

For even MORE capabilities, real-time reporting software exists as a Human Machine Interface (HMI).

Essentially, an HMI will collate and report data from your systems on the fly and construct a process diagram detailing all events that are happening. Each screen in the program is specifically labeled and personalized for your facility. The 3D images, drawn to scale, will allow more accuracy in finding a problem in your system. Along with live statuses of your system, an alarm log, statistics page, and system information are provided.

If you’re thinking about software and hardware additions to a conveyor line, rest assured, there are plenty of effective solutions to customize your system precisely for your needs and goals.

Accurate Distribution

Divert conveyor systems are high-output machines that use a variety of methods to move product from one line to an outfeeding line. Downstream from printing and labeling solutions, before entering a divert section, the box passes through a scan tower and the shipping barcode is read. This tells the conveyor where to divert the box. If any packages go unread, or an error happens, they’ll typically be recirculated or put off onto a pick line for re-processing.

The only other solution that can match the throughput and divert rate of this type of conveyor are certain shuttle systems (which are more for picking rather than distribution). Enabling this sort of automation completes processing exponentially quicker than manual operations, and typically possesses a 1% error rate- impressively low

The main difference with sortation conveyors is the method of how the product is handled. Depending on the size of the carton, fragility, and direction it needs to be facing- a multitude of diverting functions are used.

Tailored Engineering

When a turnkey solution like a conveyor system is engineered for a distribution center, the conveyor system is designed specifically for your warehouse. While many solutions exist, they may follow more of a “one size fits all” approach. In reality, every distribution center varies drastically from one to another, and a general automation solution that works for some, may not work for others.

Conveyors are unique in the sense that they can be scaled precisely to what’s needed. Want to simply move cartons from one area to another? A straight section of powered conveyor would probably work out just fine. Need to fulfill orders and divert to multiple EOL loading bays? No problem.

In comparison to robotic fulfillment, the answer would be to deploy another AGV/AMR system to meet demand. It’ll most likely perform as needed, but it won’t be as carefully executed as a well-engineered conveyor system.

If your distribution center is researching automation that is flexible, durable, and rapid, consider how a conveyor could fit into your warehouse space and current operations. Century Conveyor Systems has been engineering efficient conveyor systems for over 40 years, and we’re more than capable to tackle your material handling automation needs.